- TRANG CHỦ

- GIỚI THIỆU

- SẢN PHẨM

- Nguyên liệu ngành nhựa

- Hóa chất ngành Giấy

- Trợ bảo lưu và thoát nước

- Chất tăng bền ướt

- Chất phủ lô

- Hóa chất giặt chăn lưới

- Chất diệt khuẩn

- Tăng trắng huỳnh quang

- Lơ tím, xanh

- Trợ chống thấm bề mặt

- Phẩm màu cho giấy bao bì

- Phẩm màu cho giấy bìa màu

- Hóa chất cho giấy tráng phủ

- Chất phá bọt

- Chất tăng bền khô

- Hóa chất xử lý nước thải

- Chất phân tán Tissue

- Chất khử mực

- Hóa chất ngành sơn

- Nguyên liệu xi măng

- Hóa chất công nghiệp

- Hóa chất ngành dệt nhuộm

- TIN TỨC

- KỸ THUẬT

- KHÁCH HÀNG

- TUYỂN DỤNG

- LIÊN HỆ

DANH MỤC SẢN PHẨM

TÀI LIỆU KỸ THUẬT

- tdsp640j.pdf

- propertyanalysiswt45ancalpha.pdf

- tdspalmac1600alpha.pdf

- tdspalmac1500alpha.pdf

- stearicacid1838alpha.pdf

- coaofstearicacidr401860alpha.pdf

- deepwhiteabpxpowderalpha.pdf

- kymenẹ57htangbenuotvn.pdf

- prosofttq28881.pdf

- tdskymene705.pdf

- kymenẹ57htds.pdf

- hyt80tdsenalpha.pdf

- snowhite80tdsvietnam.pdf

- pmmacm207.pdf

- pc110uiso.pdf

- opticalbrighteningagent2plc.docx

- opticalbrighteningagent4plcvn.pdf

- melaminetdsalpha.pdf

- coazncl2alpha.jpg

- tdszncl2alpha.pdf

- pc1220ueng.pdf

- pc1100u.pdf

- pc1070ueng.pdf

- absag15átds.pdf

- ppk8009tdsen.pdf

- absterlurangp35.pdf

- absterlurangp22.pdf

- bakelit161jcoaalpha.pdf

- bakelit151jcoaalpha.pdf

- bakelit141jcoaalpha.pdf

- bakelit141coaalpha.pdf

- makrolonet3117isoen.pdf

- makrolonet3113isoen.pdf

- makrolonal2647isoen.pdf

- makrolon2807isoen.pdf

- makrolon2407isoen.pdf

- alphavncompanyprofile.pdf

- Paper Chemicals

- Water treatment Chemicals

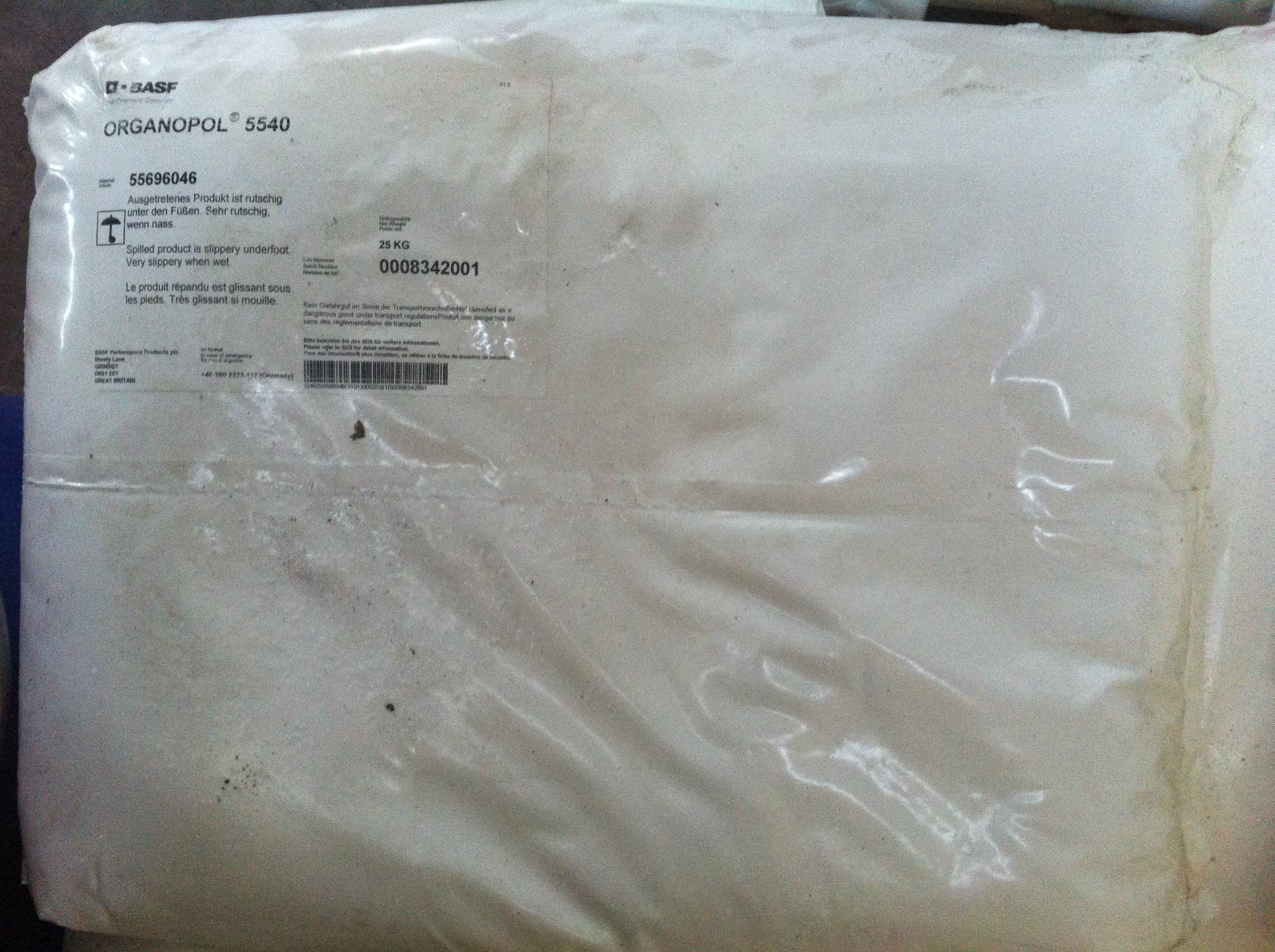

Organopol® 5540, Anion PAM, 25kg/bag

| Tên sản phẩm: | Organopol® 5540, Anion PAM, 25kg/bag |

|---|---|

| Mã sản phẩm | Organopol® 5540 |

| Nhóm sản phẩm: | Water treatment Chemicals |

| Lượt xem | 2843 |

| Mua hàng | |

Technical Information

Organopol® 5540

Chemical nature

Copolymer of acrylamide and sodiumacrylate

Physical form: Solid Grade Polymer

Ionic charge: Anionic

Solubility in water: Excellent.

Technical Data

| Appearance | White GranularPowder |

| Ionic charge | anionic |

| MolecularWeight | Ultra High |

| Particle Size | 98 % < 1400 microns |

| Bulk Density | 0.65 g/cm³ |

| pH-value of a0.5 % solution | min. 5.0 |

This information only indicates a typicalproperty of the product and MUST NOTbe taken as specification.

Storage

Recommended solution concentrations

Stock Solution: 0.15 – 0.30 % max.

Feed Solution: 0.01 – 0.05 % max.

Recommended storage periods

Stock Solution: 1 – 2 days

Dry Polymer: up to 2 years

Storage of polymer should be in a cool,dry place.

Materials:

According to our experience to date,stainless steel (AISI 316 Ti or AISI 321), polyester (Palatal® A 410), polyethylene (Lupolen®), polypropylene and rigid PVC can be used for tanks and pipework.

Areas of application

Organopol 5540 is a non-toxic highmolecular weight anionic polyacrylamideflocculant supplied as free flowing,non-dusting granules with excellent solubility. Organopol 5540 provides superior floc strength, colloidal retention,and solids separation in mill process water treatment programs.

Anionic polymer for the paper and pulpmill process water treatment programs in fine paper, newsprint, mechanical specialties and paperboard grades. InDAF clarification applications, designed for polymer addition at last shear pointprior to clarification at dosage rates of 0.5 to 5 ppm based on process waterflow. Recommended in single/dual component and bentonite microparticle clarification systems. Also applied as a polymer flocculant for enhancing the efficiency of effluent sludge dewatering systems.

Benefits

-Improves process equipment outputand runnability for return on investment.

- Superior clarification of processwater in dissolved air flotation (DAF)systems.

- Enhances sludge dewatering efficiencyin treatment of mill effluents.

- Provides stable clarification conditionsfor removing suspended anddissolved solids.

- Enhances rapid flotation in DAFclarifiers for energy savings in air compressor operation.

- Improves deink pulp uniformitythrough efficient clarification of ink,ash, and stickies.

- Performs over a wide pH range withor without the use of organic and inorganiccoagulants.

Effectively decreases BOD/CODlevels in clarified process effluentstreams.

- Maximum flexographic ink clarificationfrom washer effluent in thedeinking process.

- Contains no VOC or surfactantcomponents to harm the environment.

-Available in a variety of packaging forease of handling and safety.

Sản phẩm khác cùng loại

- Hiện chưa có sản phẩm

HỖ TRỢ TRỰC TUYẾN

Hotline: 0904 022 133

Hotline: 0904 022 133 Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103

Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105

Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Fax: +8424.37767744

Fax: +8424.37767744 Email:

Email:- Facebook Hóa Chất Alpha

-

binh.alpha

binh.alpha

TÌM KIẾM NÂNG CAO

NHẬN TIN SẢN PHẨM MỚI

HOẠT ĐỘNG

- Thông báo nghỉ Tết Nguyên Đán Canh Tý 2019

- Tuyển Trưởng phòng kinh doanh hạt nhựa kỹ thuật - Business Manager

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh hóa chất, hạt nhựa

- Tuyển Nhân viên kinh doanh hóa chất

- Tuyển nhân viên kinh doanh hóa chất, hạt nhựa

- Thay đổi tên công ty và địa chỉ văn phòng

- Đoàn Hiệp hội Giấy Việt Nam tham dự FAPPI 31 tại Indonesia

- Công ty cổ phần giấy việt trì 50 năm xây dựng và phát triển

- Công ty CP giấy Việt Trì tự hào với truyền thống 50 năm xây dựng và phát triển

- Triển lãm China International Water Chem Exhibition 2013 lần thứ 9

LIÊN KẾT WEBSITE

- Công ty Cổ phần XNK Bắc Giang (Nhà máy Giấy Xương Giang)

- Công ty Cổ phần DEVYT (Nhà máy Giấy BBP)

- Công ty Cổ phần Giấy An Hòa

- Công ty Cổ phần Giấy Bao bì Đồng Tiến

- Công ty Giấy Tissue Sông Đuống

- Công ty TNHH Xưởng Giấy Chánh Dương

- Tập đoàn Giấy Tân Mai

- Công ty TNHH Giấy Trường Xuân

- Công ty TNHH Giấy Kraft Vina

- Công ty Giấy Hải Phòng

- Tổng công ty Giấy Việt Nam (Nhà máy Giấy Bãi Bằng)

- Công ty Cổ phần Giấy Việt Trì

- Trang Web Danh bạ các công ty hóa chất

- Công ty Cổ phần Giấy Sài Gòn

- Công ty cổ phần Sản xuất và thương mại P.P

- Công ty cổ phần Giấy Vạn Điểm

- Thời báo kinh tế - Diễn đàn Doanh Nghiệp Việt Nam

- Giấy – Wikipedia tiếng Việt

- Hiệp hội giấy và bột giấy Việt Nam (VPPA)

- Tin tuc 24h | tin nhanh bong da | the thao | thoi trang, giai tri vn

- Báo Dân trí – Thông tin mọi lúc, mọi nơi tới mọi người, mọi nhà

- Tin nhanh VnExpress - Đọc báo, tin tức online 24h

LƯỢT TRUY CẬP

- Đang xem

- Hôm nay 684

- Tổng lượt truy cập 3,994,864

THÔNG TIN TIỆN ÍCH

BÀI VIẾT MỚI NHẤT

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh Hóa chất, Hạt nhựa

- PAC và ứng dụng trong xử lý nước

- Cần tuyển nhân viên kinh doanh hóa chất, nhựa

- Tuyển 01 lái xe văn phòng

- Xử lý nước thải sản xuất giấy

- Lịch sử sản xuất giấy

- Các chất phụ gia trong ngành giấy

- List of Customers

- Nhựa thông trong kỹ thuật gia keo bề mặt cho giấy

- Nguyên nhân và cơ chế của hiện tượng bóc sợi

- Các bệnh giấy thường gặp và cách khắc phục

- Keo chống thấm AKD

- Chất độn cho giấy

- Nhuộm màu cho Giấy

- Khách hàng

- 6-8/6/2013: Triển lãm Quốc tế về ngành Giấy và Bột giấy Việt Nam

- Chất trợ bảo lưu Percol 182

- Tuyển 01 nhân viên kinh doanh hóa chất

Bình luận

Chưa có bình luận nào!

Phản hồi

Bình luận từ Facebook