- TRANG CHỦ

- GIỚI THIỆU

- SẢN PHẨM

- Nguyên liệu ngành nhựa

- Hóa chất ngành Giấy

- Trợ bảo lưu và thoát nước

- Chất tăng bền ướt

- Chất phủ lô

- Hóa chất giặt chăn lưới

- Chất diệt khuẩn

- Tăng trắng huỳnh quang

- Lơ tím, xanh

- Trợ chống thấm bề mặt

- Phẩm màu cho giấy bao bì

- Phẩm màu cho giấy bìa màu

- Hóa chất cho giấy tráng phủ

- Chất phá bọt

- Chất tăng bền khô

- Hóa chất xử lý nước thải

- Chất phân tán Tissue

- Chất khử mực

- Hóa chất ngành sơn

- Nguyên liệu xi măng

- Hóa chất công nghiệp

- Hóa chất ngành dệt nhuộm

- TIN TỨC

- KỸ THUẬT

- KHÁCH HÀNG

- TUYỂN DỤNG

- LIÊN HỆ

DANH MỤC SẢN PHẨM

TÀI LIỆU KỸ THUẬT

- tdsp640j.pdf

- propertyanalysiswt45ancalpha.pdf

- tdspalmac1600alpha.pdf

- tdspalmac1500alpha.pdf

- stearicacid1838alpha.pdf

- coaofstearicacidr401860alpha.pdf

- deepwhiteabpxpowderalpha.pdf

- kymenẹ57htangbenuotvn.pdf

- prosofttq28881.pdf

- tdskymene705.pdf

- kymenẹ57htds.pdf

- hyt80tdsenalpha.pdf

- snowhite80tdsvietnam.pdf

- pmmacm207.pdf

- pc110uiso.pdf

- opticalbrighteningagent2plc.docx

- opticalbrighteningagent4plcvn.pdf

- melaminetdsalpha.pdf

- coazncl2alpha.jpg

- tdszncl2alpha.pdf

- pc1220ueng.pdf

- pc1100u.pdf

- pc1070ueng.pdf

- absag15átds.pdf

- ppk8009tdsen.pdf

- absterlurangp35.pdf

- absterlurangp22.pdf

- bakelit161jcoaalpha.pdf

- bakelit151jcoaalpha.pdf

- bakelit141jcoaalpha.pdf

- bakelit141coaalpha.pdf

- makrolonet3117isoen.pdf

- makrolonet3113isoen.pdf

- makrolonal2647isoen.pdf

- makrolon2807isoen.pdf

- makrolon2407isoen.pdf

- alphavncompanyprofile.pdf

- HẠT NHỰA NGUYÊN SINH

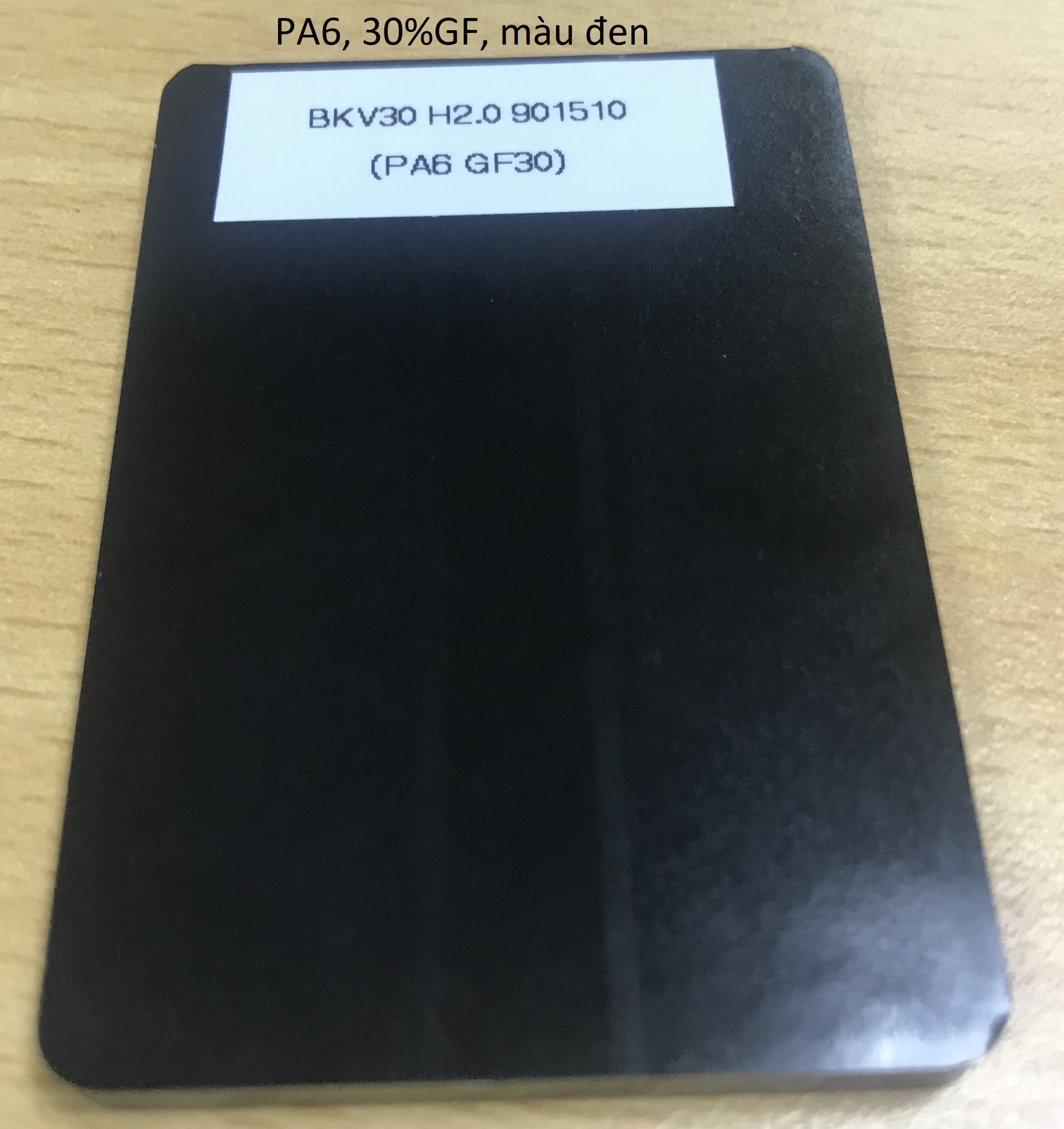

- Hạt nhựa PA6 30%GF

PA6 Durethan BKV 30 000000 (PA6, 30%GF, màu tự nhiên & màu đen)

| Tên sản phẩm: | PA6 Durethan BKV 30 000000 (PA6, 30%GF, màu tự nhiên & màu đen) |

|---|---|

| Mã sản phẩm | Durethan BKV 30 000000 |

| Nhóm sản phẩm: | Hạt nhựa PA6 30%GF |

| Lượt xem | 3513 |

| Mua hàng | |

PA6 Durethan BKV 30 000000 (PA6, 30%GF, màu tự nhiên & màu đen)

Đóng gói: 25kg/bao

Xuất xứ: Ấn Độ/Trung Quốc

|

30 % Glass fiber reinforced; injection molding grade ISO Shortname: ISO 1874-PA 6, GR, 14-100, GF30 |

|

|||||

|

Property |

Test Condition |

Unit |

Standard |

guide value d.a.m. |

cond. |

|

|

Rheological properties |

|

|

|

|

|

|

|

C Melt volume-flow rate |

260 °C; 5 kg |

cm³/(10 min) |

ISO 1133-1 |

14 |

|

|

|

Molding shrinkage, parallel |

150x105x3; 280 °C / MT 80 °C; 500 bar |

% |

acc. ISO 2577 |

0.16 |

|

|

|

Molding shrinkage, transverse |

150x105x3; 280 °C / MT 80 °C; 500 bar |

% |

acc. ISO 2577 |

0.82 |

|

|

|

Post- shrinkage, parallel |

150x105x3; 120 °C; 4 h |

% |

acc. ISO 2577 |

0.03 |

|

|

|

Post- shrinkage, transverse |

150x105x3; 120 °C; 4 h |

% |

acc. ISO 2577 |

0.12 |

|

|

|

C Molding shrinkage, parallel |

60x60x2; 280 °C / MT 80 °C; 600 bar |

% |

ISO 294-4 |

0.25 |

|

|

|

C Molding shrinkage, transverse |

60x60x2; 280 °C / MT 80 °C; 600 bar |

% |

ISO 294-4 |

0.75 |

|

|

|

Post- shrinkage, parallel |

60x60x2; 120 °C; 4 h |

% |

ISO 294-4 |

0.05 |

|

|

|

Post- shrinkage, transverse |

60x60x2; 120 °C; 4 h |

% |

ISO 294-4 |

0.1 |

|

|

|

Mechanical properties (23 °C/50 % r. h.) |

|

|

|

|

|

|

|

C Tensile modulus |

1 mm/min |

MPa |

ISO 527-1,-2 |

9800 |

|

6100 |

|

C Tensile Stress at break |

5 mm/min |

MPa |

ISO 527-1,-2 |

170 |

|

105 |

|

C Tensile Strain at break |

5 mm/min |

% |

ISO 527-1,-2 |

3.0 |

|

6.0 |

|

C Tensile creep modulus |

1 h |

MPa |

ISO 899-1 |

|

|

5100 |

|

C Tensile creep modulus |

1000 h |

MPa |

ISO 899-1 |

|

|

4100 |

|

C Charpy impact strength |

23 °C |

kJ/m² |

ISO 179-1eU |

80 |

|

95 |

|

C Charpy impact strength |

-30 °C |

kJ/m² |

ISO 179-1eU |

70 |

|

70 |

|

C Charpy notched impact strength |

23 °C |

kJ/m² |

ISO 179-1eA |

12 |

|

20 |

|

C Charpy notched impact strength |

-30 °C |

kJ/m² |

ISO 179-1eA |

10 |

|

10 |

|

Izod impact strength |

23 °C |

kJ/m² |

ISO 180-1U |

75 |

|

80 |

|

Izod impact strength |

-30 °C |

kJ/m² |

ISO 180-1U |

60 |

|

70 |

|

Izod notched impact strength |

23 °C |

kJ/m² |

ISO 180-1A |

13 |

|

20 |

|

Izod notched impact strength |

-30 °C |

kJ/m² |

ISO 180-1A |

10 |

|

10 |

|

Flexural modulus |

2 mm/min |

MPa |

ISO 178-A |

8600 |

|

5100 |

|

Flexural strength |

2 mm/min |

MPa |

ISO 178-A |

275 |

|

170 |

|

Flexural strain at flexural strength |

2 mm/min |

% |

ISO 178-A |

4.0 |

|

6.0 |

|

Flexural stress at 3.5 % strain |

2 mm/min |

MPa |

ISO 178-A |

|

|

145 |

|

C Puncture maximum force |

23 °C |

N |

ISO 6603-2 |

1071 |

|

|

|

C Puncture maximum force |

-30 °C |

N |

ISO 6603-2 |

950 |

|

|

|

C Puncture energy |

23 °C |

J |

ISO 6603-2 |

8 |

|

14 |

|

C Puncture energy |

-30 °C |

J |

ISO 6603-2 |

6 |

|

5 |

|

Ball indentation hardness |

|

N/mm² |

ISO 2039-1 |

210 |

|

100 |

|

Property |

Test Condition |

Unit |

Standard guide |

|||

|

|

|

|

|

value d.a.m. |

cond. |

|

|

Thermal properties |

|

|

|

|

|

|

|

C Melting temperature |

10 °C/min |

°C |

ISO 11357-1,-3 |

220 |

|

|

|

C Temperature of deflection under load |

1.80 MPa |

°C |

ISO 75-1,-2 |

200 |

|

|

|

C Temperature of deflection under load |

0.45 MPa |

°C |

ISO 75-1,-2 |

215 |

|

|

|

Vicat softening temperature |

50 N; 120 °C/h |

°C |

ISO 306 |

> 200 |

|

|

|

C Coefficient of linear thermal expansion, parallel |

23 to 55 °C |

10-4/K |

ISO 11359-1,-2 |

0.2 |

|

|

|

C Coefficient of linear thermal expansion, transverse |

23 to 55 °C |

10-4/K |

ISO 11359-1,-2 |

0.8 |

|

|

|

C Burning behavior UL 94 |

1.5 mm |

Class |

UL 94 |

HB |

|

|

|

C Burning behavior UL 94 |

0.75 mm |

Class |

UL 94 |

HB |

|

|

|

C Oxygen index |

Method A |

% |

ISO 4589-2 |

22 |

|

|

|

Glow wire test (GWFI) |

2.0 mm |

°C |

IEC 60695-2-12 |

600 |

|

|

|

Burning behavior US-FMVSS302 |

>=1.0 mm |

|

ISO 3795 |

passed |

|

|

|

C Vicat softening temperature |

50 N; 50 °C/h |

°C |

ISO 306 |

200 |

|

|

|

Electrical properties (23 °C/50 % r. h.) |

|

|

|

|

|

|

|

C Relative permittivity |

100 Hz |

- |

IEC 60250 |

4.0 |

|

10 |

|

C Relative permittivity |

1 MHz |

- |

IEC 60250 |

4.0 |

|

5.0 |

|

C Dissipation factor 100 Hz 10-4 IEC 60250 |

50 |

2000 |

||||

|

C Dissipation factor 1 MHz 10-4 IEC 60250 |

150 |

1200 |

||||

|

C Volume resistivity |

|

Ohm·m |

IEC 60093 |

1E13 |

1E10 |

|

|

C Surface resistivity |

|

Ohm |

IEC 60093 |

1E14 |

1E12 |

|

|

C Electric strength |

1 mm |

kV/mm |

IEC 60243-1 |

40 |

35 |

|

|

C Comparative tracking index CTI |

Solution A |

Rating |

IEC 60112 |

600 |

|

|

|

Comparative tracking index CTI M |

Solution B |

Rating |

IEC 60112 |

400 M |

|

|

|

Other properties (23 °C) |

|

|

|

|

|

|

|

C Water absorption (Saturation value) |

Water at 23 °C |

% |

ISO 62 |

7.0 |

|

|

|

C Water absorption (Equilibrium value) |

23 °C; 50 % RH |

% |

ISO 62 |

2.1 |

|

|

|

C Density |

|

kg/m³ |

ISO 1183 |

1360 |

|

|

|

Bulk density |

|

kg/m³ |

ISO 60 |

700 |

|

|

|

Processing conditions for test specimens |

|

|

|

|

|

|

|

C Injection molding-Melt temperature |

|

°C |

ISO 294 |

280 |

|

|

|

C Injection molding-Mold temperature |

|

°C |

ISO 294 |

80 |

|

|

|

Processing recommendations |

|

|

|

|

|

|

|

Drying temperature dry air dryer |

|

°C |

- |

80 |

|

|

|

Drying time dry air dryer |

|

h |

- |

2-6 |

|

|

|

Residual moisture content |

|

% |

Acc. to Karl Fischer |

0.03-0.12 |

|

|

|

Melt temperature (Tmin - Tmax) |

|

°C |

- |

270-290 |

|

|

|

Mold temperature |

|

°C |

- |

80-120 |

|

|

C These property characteristics are taken from the CAMPUS plastics data bank and are based on the international catalogue of basic data for plastics according to ISO 10350.

Sản phẩm khác cùng loại

- Hiện chưa có sản phẩm

HỖ TRỢ TRỰC TUYẾN

Hotline: 0904 022 133

Hotline: 0904 022 133 Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103

Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105

Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Fax: +8424.37767744

Fax: +8424.37767744 Email:

Email:- Facebook Hóa Chất Alpha

-

binh.alpha

binh.alpha

TÌM KIẾM NÂNG CAO

NHẬN TIN SẢN PHẨM MỚI

HOẠT ĐỘNG

- Thông báo nghỉ Tết Nguyên Đán Canh Tý 2019

- Tuyển Trưởng phòng kinh doanh hạt nhựa kỹ thuật - Business Manager

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh hóa chất, hạt nhựa

- Tuyển Nhân viên kinh doanh hóa chất

- Tuyển nhân viên kinh doanh hóa chất, hạt nhựa

- Thay đổi tên công ty và địa chỉ văn phòng

- Đoàn Hiệp hội Giấy Việt Nam tham dự FAPPI 31 tại Indonesia

- Công ty cổ phần giấy việt trì 50 năm xây dựng và phát triển

- Công ty CP giấy Việt Trì tự hào với truyền thống 50 năm xây dựng và phát triển

- Triển lãm China International Water Chem Exhibition 2013 lần thứ 9

LIÊN KẾT WEBSITE

- Công ty Cổ phần XNK Bắc Giang (Nhà máy Giấy Xương Giang)

- Công ty Cổ phần DEVYT (Nhà máy Giấy BBP)

- Công ty Cổ phần Giấy An Hòa

- Công ty Cổ phần Giấy Bao bì Đồng Tiến

- Công ty Giấy Tissue Sông Đuống

- Công ty TNHH Xưởng Giấy Chánh Dương

- Tập đoàn Giấy Tân Mai

- Công ty TNHH Giấy Trường Xuân

- Công ty TNHH Giấy Kraft Vina

- Công ty Giấy Hải Phòng

- Tổng công ty Giấy Việt Nam (Nhà máy Giấy Bãi Bằng)

- Công ty Cổ phần Giấy Việt Trì

- Trang Web Danh bạ các công ty hóa chất

- Công ty Cổ phần Giấy Sài Gòn

- Công ty cổ phần Sản xuất và thương mại P.P

- Công ty cổ phần Giấy Vạn Điểm

- Thời báo kinh tế - Diễn đàn Doanh Nghiệp Việt Nam

- Giấy – Wikipedia tiếng Việt

- Hiệp hội giấy và bột giấy Việt Nam (VPPA)

- Tin tuc 24h | tin nhanh bong da | the thao | thoi trang, giai tri vn

- Báo Dân trí – Thông tin mọi lúc, mọi nơi tới mọi người, mọi nhà

- Tin nhanh VnExpress - Đọc báo, tin tức online 24h

LƯỢT TRUY CẬP

- Đang xem

- Hôm nay 1163

- Tổng lượt truy cập 4,036,566

THÔNG TIN TIỆN ÍCH

BÀI VIẾT MỚI NHẤT

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh Hóa chất, Hạt nhựa

- PAC và ứng dụng trong xử lý nước

- Cần tuyển nhân viên kinh doanh hóa chất, nhựa

- Tuyển 01 lái xe văn phòng

- Xử lý nước thải sản xuất giấy

- Lịch sử sản xuất giấy

- Các chất phụ gia trong ngành giấy

- List of Customers

- Nhựa thông trong kỹ thuật gia keo bề mặt cho giấy

- Nguyên nhân và cơ chế của hiện tượng bóc sợi

- Các bệnh giấy thường gặp và cách khắc phục

- Keo chống thấm AKD

- Chất độn cho giấy

- Nhuộm màu cho Giấy

- Khách hàng

- 6-8/6/2013: Triển lãm Quốc tế về ngành Giấy và Bột giấy Việt Nam

- Chất trợ bảo lưu Percol 182

- Tuyển 01 nhân viên kinh doanh hóa chất

Bình luận

Chưa có bình luận nào!

Phản hồi

Bình luận từ Facebook